A lot of changes are happening quickly and significantly in the coil production sector right now. These changes are mostly caused by better technology and new needs in the industry. Innovation is very important in the coil production business because companies are always looking for ways to be more efficient, last longer, and save money. The goal of this blog is to look at the most important new ideas and technologies that are about to change the business of making coils.

The coil manufacturing sector is being revolutionized by automation. By automating coil winding processes, manufacturing lines are becoming more precise and efficient while cutting down on labor expenses and human mistakes. These high-tech devices improve the winding process for different kinds of coils by adjusting settings in real time. This change expedites production while simultaneously guaranteeing constant product quality, which is essential for custom coil manufacturers that want to effectively satisfy the different demands of their customers.

Smart manufacturing is coordinated with the coil creation area, encouraging a more interconnected and straightforward assembling environment. This innovation uses the Internet of Things (IoT) to monitor equipment and creation processes constantly. By utilizing sensors and data analytics, makers can foresee maintenance needs and prevent margin time, guaranteeing a steady production flow. Smart factories represent a significant leap forward for Coil Winding Manufacturers, who can now manage resources more effectively and improve overall productivity.

Sustainability is becoming more important in the production business because of rules and user tastes for eco-friendly products. The business that makes coils is using more and more eco-friendly products and methods that use less energy. Metals that can be recycled and insulation materials that break down naturally are being looked into by producers who want to reduce their impact on the environment. As a Trusted electric coil supplier, the use of green production practices not only contributes to environmental preservation but also corresponds with the increasing customer inclination towards sustainable goods.

A crucial part of the progress of coil production is the discovery of novel materials. Superconductors and high-performance alloys are gaining popularity due to their exceptional thermal and electrical characteristics. More efficient, long-lasting, and extreme-condition-ready coils are now within reach, all thanks to these materials. Research into composites and nanomaterials will prompt stunningly better-made coil execution, which will have new purposes in fields including energy, aviation, and automotive.

The coil manufacturing industry is now undergoing the optimization of several production process components to enhance their efficiency, driven by the effect of artificial intelligence (AI). Artificial intelligence systems can evaluate extensive amounts of data, enabling them to engage in automated decision-making, trend prediction, and design refinement. Due to their possession of this specialized knowledge, makers of customized coils are able to more accurately customize their goods to meet the unique needs of each client. Manufacturers see this skill as very beneficial. Moreover, quality control systems operated by artificial intelligence have the potential to identify flaws that are invisible to the naked human eye. This practice guarantees that only coils of superior quality are made available for purchase in the market.

Added substance production, which is additionally called 3D printing, could alter the way that how coils are made easier to make it simpler to make more chaotic shapes and velocities up the prototype process. With this innovation, makers can make complex coil shapes that were unimaginable or did not merit the cash to make previously. Because it is flexible by nature, 3D printing technology speeds up the production of customized coils in smaller amounts. This cuts down on waste and may speed up the creation process.

Technologies like automation, smart manufacturing, sustainability, improved materials, AI, and 3D printing will make coil manufacturing more inventive and efficient. The industry will expand and change as these advances continue. Partnering with a forward-thinking company like qualitycoils.com can give the skills and solutions needed to succeed in this dynamic industry. They are a Trusted electric coil provider that uses the newest technologies and trends to make each coil with quality and originality.

Innovations in electronics are always improving the functionality and efficiency of electronic equipment, contributing to an ever-expanding field of study. Recent innovations, like as tape-wrapped coil technology, have had a huge impact. These Coils are more than just a component; they are a representation of how far technology has come in the realm of devices, opening up a world of benefits and possibilities that were previously unimaginable.

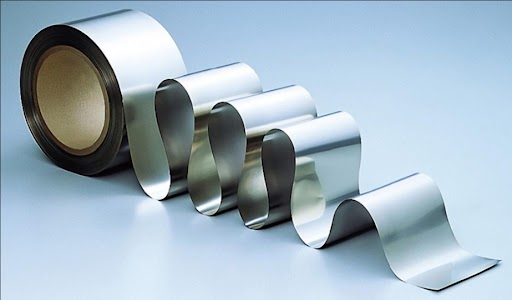

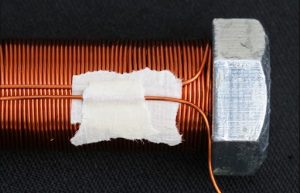

Wrapped in Tape Electromagnetic coils encased in a specially developed tape material provide insulation and protection; this kind of coil is known as a coil. In situations when the coils are subjected to harsh circumstances or high temperatures, this wrapping strategy is crucial for ensuring their life and reliability.

The tape material often used exhibits heat resistance and has exceptional electrical insulating characteristics, making it very suitable for application in electronic equipment.

The novelty of Tape Wrapped Coils is in their configuration and production procedure. Tape Wrapped Coils manufacturers have devised methodologies to accurately encase the coils with adhesive tape, so guaranteeing a consistent and secure wrapping that amplifies the coil’s operational efficiency. The enhanced accuracy in the manufacturing process has resulted in the development of coils that exhibit more compactness, efficiency, and the ability to accommodate larger currents and voltages compared to their previous iterations.

Innovative tape wrapped coils are used in a diverse array of electrical gadgets and systems among many applications. Electrodes are often used in various applications such as transformers, inductors, motors, and solenoids, where they assume a pivotal function in the conversion of energy and processing of signals. Moreover, their small dimensions and exceptional effectiveness render them well-suited for utilization in portable electronic gadgets, medical apparatus, and automobile electronics.

The increasing need for Tape Wrapped Coils of superior quality has given rise to specialist producers that prioritize the production of these coils with meticulousness and uniformity. To ensure their coils meet the high requirements of modern electronics, the producers utilize advanced procedures and materials. The experts work closely with their clients to understand their specific needs and then provide customized solutions that work for their specific uses.

The importance of Tape Wrapped Coils is anticipated to expand more as the electronics industry undergoes ongoing evolution. The increasing emphasis on downsizing and enhanced efficiency has positioned these coils to assume a crucial function in the advancement of forthcoming electronic gadgets. Researchers and manufacturers are consistently engaged in the exploration and advancement of novel materials and methodologies to augment the performance and functionalities of Tape tape-wrapped coils, hence assuring their sustained prominence in the realm of electronic component technology.

Tape Wrapped Coils serve as a notable illustration of how innovation may propel the advancement of the electronics sector. Due to their distinctive characteristics and extensive array of uses, they are an essential element in contemporary electronics. As society continues to explore the limits of what can be achieved, firms such as qualitycoils.com are leading the way by offering Tape Wrapped Coils of superior quality that align with the requirements of the contemporary technology-driven society.

The world of electrical engineering is constantly evolving, and at the heart of this transformation are innovations in components like coils. Coils, an essential part of countless electronic devices, have seen their fair share of advancements over the years. One such breakthrough in coil technology is the use of tape-wrapped coils. In this article, we will delve into the world of innovative tape-wrapped coils and introduce you to a leading tape-wrapped coils manufacturer.

The Evolution of Coils: Coils, in their most basic form, are loops of wire wound around a core. They play a crucial role in various applications, including transformers, conductors, and electromagnets. Traditionally, coils were wound using bare wire, which had its limitations in terms of electrical insulation and mechanical protection.

However, the advent of tape-wrapped coils has brought a paradigm shift to the industry. These coils are constructed by wrapping layers of insulating tape around the wire winding. This innovation has opened up a world of possibilities and advantages for engineers and manufacturers alike.

Advantages of Tape-Wrapped Coils:

Tape-Wrapped Coils Manufacturer: When it comes to sourcing high-quality tape-wrapped coils, their name stands out as a leading manufacturer in the industry. Quality Coils specializes in producing innovative tape-wrapped coils that meet the stringent demands of modern electrical engineering.

Conclusion:

Innovative tape-wrapped coils have revolutionized the world of electrical components, offering improved insulation, enhanced mechanical protection, and a wide range of customization options. When it comes to sourcing these cutting-edge coils, QualityCoils.com is the go-to destination for engineers and manufacturers seeking high-quality, reliable solutions. With their commitment to excellence and precision manufacturing, Quality Coils is setting new standards in the tape-wrapped coil industry. Visit their website to explore their product range and experience the future of coil technology.

The CT manufacturing sector plays a significant role in the state’s economy. Assembler careers and positions in Connecticut are at the heart of this thriving sector, offering numerous opportunities for individuals looking to build a bright and promising future.

Assembler Careers in CT: Assembler careers in Connecticut are in high demand and are often considered the backbone of the state’s manufacturing industry. Assemblers are skilled professionals responsible for putting together various components to create products ranging from electronic devices to machinery. Their accuracy and meticulousness are crucial for ensuring the final product’s quality and functionality.

These careers typically require a combination of technical skills and manual dexterity. Assemblers in CT may work in a variety of industries, including aerospace, electronics, automotive, and medical device manufacturing. They are essential to the manufacturing process because they guarantee that the finished goods satisfy the requirements.

One of the key benefits of pursuing an assembler career in Connecticut is the availability of numerous job opportunities. The state’s strong manufacturing sector continually seeks skilled assemblers to meet the growing demands of various industries. This demand ensures a stable job market and the potential for career advancement.

Assembler Positions in CT: Assembler positions in Connecticut come in various forms, each offering unique challenges and opportunities for career growth. Some common assembler positions include:

Conclusion:

In conclusion, assembler careers and positions in Connecticut offer an excellent opportunity for individuals seeking stable and rewarding employment in the manufacturing sector. Connecticut’s strong manufacturing industry ensures a constant demand for skilled assemblers across various fields, including electronics, aerospace, medical devices, and automotive.

If you are interested in pursuing an assembler career in Connecticut or looking for assembler positions, you can explore job opportunities and further information on the website qualitycoils.com. Whether you are just starting your career or seeking a new opportunity, Connecticut’s assembler positions provide a pathway to a promising and prosperous future in the manufacturing sector of the Constitution State.

When it comes to the intricate world of electrical engineering and electromagnetism, precision and reliability are paramount. One of the key components that play a pivotal role in various applications is the electric coil. Electric coils, often referred to as electromagnetic coils, are essential in powering devices and systems across multiple industries. The article will examine the value of skilled electric coil makers and their contributions to the industry.

Experienced Electric Coil Manufacturers: Experienced electric coil manufacturers are the unsung heroes of the electrical industry. These companies have honed their skills over decades, if not centuries, in creating coils that adhere to the highest requirements for performance and quality. Their expertise lies not only in producing standard coils but also in customizing solutions to meet the unique requirements of their customers.

The key to the success of these manufacturers is their in-depth knowledge of the physics behind electromagnetism. They understand how to wind conductive wire into coils, considering factors like wire gauge, the number of turns, and the core material. This expertise ensures that the coils they produce are not only efficient but also durable, capable of withstanding rigorous operating conditions.

Electromagnetic Coils Manufacturer: Particularly in industrial automation and medical equipment, magnetic coils are used in a wide range of applications. These coils are the brains of things like solenoids, relays, and transformers because they are made to produce magnetic fields when an electric current passes through them. An experienced electromagnetic coils manufacturer is well-versed in the nuances of these applications.

One of the most critical aspects of electromagnetic coils is their ability to produce consistent and robust magnetic fields. This characteristic is vital in devices like MRI machines, where image clarity depends on the uniformity of the magnetic field. It is also crucial in industrial settings where electromagnetic coils control the movement of machinery and equipment. Experienced manufacturers understand the science behind achieving this precision.

The Intersection of Experience and Technology: In the modern era, experienced electric coil and electromagnetic coil manufacturers combine their traditional craftsmanship with cutting-edge technology. Advanced computer-aided design (CAD) and computer numerical control (CNC) machines enable them to produce coils with unmatched precision. Their goods constantly meet or surpass industry requirements because of this combination of experience and technology. Furthermore, these manufacturers often invest in research and development to stay ahead of the curve. They are continually exploring new materials and manufacturing techniques to improve coil performance, reduce energy consumption, and enhance durability. This commitment to innovation makes them invaluable partners for companies across various sectors.

Conclusion:

Experienced electric coil manufacturers and electromagnetic coil manufacturers play a pivotal role in the world of electrical engineering. Their expertise, combined with technological advancements, leads to the creation of reliable and efficient coils that power our modern world. When seeking top-quality electric coils and electromagnetic coils, it’s essential to turn to trusted sources. One such source is QualityCoils.com, a leading manufacturer known for its dedication to excellence and commitment to delivering top-notch solutions. Whether you are in need of standard electric coils or highly specialized electromagnetic coils, experienced manufacturers like those at Quality Coils Inc know and have the skills to meet your requirements. Their legacy of excellence and unwavering commitment to quality makes them an excellent choice for industries relying on precision electrical components.