These days, unique and personalized solutions are more important than ever because technology is always changing. Custom coil assemblies are important parts that are used in many fields, such as medicine, the car industry, and others. In addition to meeting the bare minimum requirements, these unique solutions try to push the limits of what is possible, promise peak performance, and give you an edge over other companies.

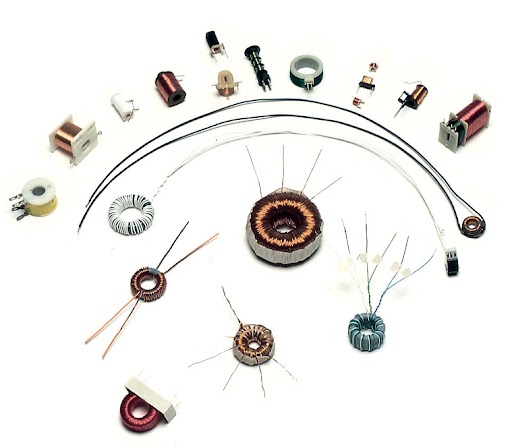

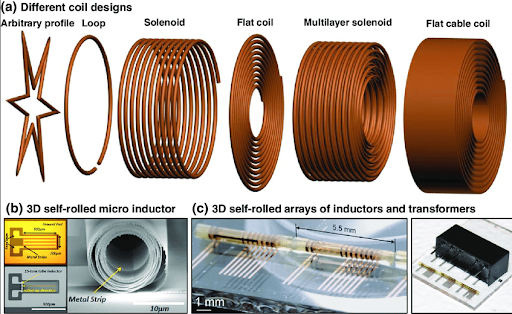

Electromagnetic induction is the main idea behind custom coil systems. The coils are made of metals like copper or aluminum and are carefully formed into exact shapes so that when an electric current flows through them, magnetic fields are created. The customization part comes into play when these coils are changed to fit the specific needs of different uses. This includes changing their size, shape, and electrical properties.

Custom coil windings hold together these systems. There isn’t a single size that fits all; instead, they are carefully designed to fit the needs of each purpose. Customizing coil windings is what makes these solutions unique, whether it’s a tight winding for a small area or a certain pattern to get a certain magnetic field.

Copper is often used for custom-made coils because it is a good conductor of electricity. Companies that make Custom Wound Copper Coil manufacturers are sought after in fields where dependability and high effectiveness are very important. Precision and quality are very important to companies that make these coils, and they make sure that every coil meets their customers’ strict needs.

Custom electric coil solutions are at the heart of driving progress in many areas. These customized solutions are made to give specific applications the exact performance traits they need. Custom electric coil solutions are the answer to tough problems in a wide range of areas, from medical devices that need precise magnetic fields to car parts that need to work in harsh conditions.

The great thing about handmade coil systems is that they can be changed to fit specific needs. This customization isn’t limited to the coils’ looks; it also includes their electrical qualities, how they handle heat, and how they’re built into the final product. With this level of tailoring, each coil assembly is not just a part but a solution that makes the application run better and more efficiently as a whole.

Making handmade coil systems isn’t just about making things; it takes skill and creativity. To do this, you need to know a lot about electromagnetics, materials science, and the needs of the application. Custom solutions manufacturers often work closely with their clients, using their knowledge to come up with new ideas and create truly unique solutions.

In a world where people want more and more customized solutions, custom coil systems stand out as an important part of driving success and innovation. These systems are special because they can be changed to fit specific needs. This is true for custom coil windings, custom-made copper coils, and custom electric coil solutions. If you want the best quality and accuracy in custom coil systems, qualitycoils.com is the name you can trust. They offer options that are expertly made to meet the highest standards.

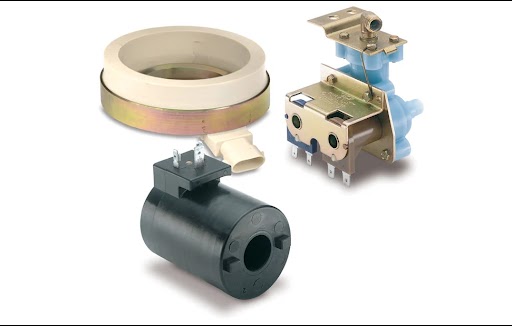

Encapsulated coils have become indispensable in electrical engineering for a wide range of uses in many different sectors. Because of these coils, which are long-lasting and efficient, new technologies and production methods have become possible. We investigate the relevance of encapsulated coils in several areas and dig into their varied universe in this blog.

Before you can look into their uses, you need to know what enclosed coils are and why people like them. When a polymer or plastic layer surrounds the coil and keeps it from being exposed to dust, chemicals, or water, this is called encapsulation. It works better and lasts longer because of this process, which makes it great for tough jobs.

Encapsulated electric coil supplier are essential in the telecom sector for maintaining continuous and clear communication. Their resistance to electromagnetic interference is vital in devices that employ them, such as inductors, filters, and transformers. To ensure that the loops can persevere through the mileage of nonstop utilization and different climatic circumstances, they are epitomized.

The use of enclosed coils in diverse automobile components has precipitated a fundamental transformation within the industry. The coils above are of paramount importance in electric power steering and ignition systems, hence enhancing the efficiency and safety of automobiles. The encapsulation of coils renders them a reliable choice for automotive applications, as it enables them to endure elevated temperatures and vibrations.

This technical development revolves around producers of enclosed coils. They use cutting-edge methods to make coils that can withstand the rigorous standards of many sectors. To make sure the encapsulated coils work as well as possible, the procedure requires exacting engineering and meticulous material selection.

Image and surgical equipment are only two of the many medical gadgets that rely on Encapsulated coil manufacturer. Essential in healthcare settings, encapsulation offers a hygienic barrier. In addition, these coils’ accuracy and dependability are vital for the safety and accuracy of medical treatments.

Encapsulated Electric Coils suppliers are vital in ensuring that many different sectors have access to these components. Their tight collaboration with manufacturers guarantees a reliable supply of high-quality coils tailored to each customer’s requirements.

The aeronautic industry requests parts that can perform immaculately under outrageous circumstances. Exemplified curls are utilized in different aviation applications, including communication systems, navigation equipment, and flight control frameworks.

Epitomized curls are turning out to be more significant in environmentally friendly power frameworks as the globe moves towards more manageable energy sources. Wind turbines and solar inverters rely on them because of the long life and high efficiency they provide to these systems. The encapsulation shields the coils from damaging outside elements, extending their life and guaranteeing their dependability.

Beyond the stated sectors, encapsulated coils have a wide range of uses. Innovation and technical breakthroughs are propelled by their effectiveness, durability, and adaptability, which make them a popular option in numerous areas. Providing high-quality encapsulated coils that power industries worldwide, organizations like qualitycoils.com stay at the forefront as we continue to explore new possibilities.

The world of coil production is always changing because technology is improving quickly, and people want more accuracy and dependability. Electric coil makers with a lot of experience are at the heart of this business. They are responsible for driving innovation and making sure that the goods they make meet the highest quality standards. Out of these early adopters, Quality Coils, Inc. stands out as a star. Its new ways of designing and making coils keep it ahead of the game.

Proficiency is an essential determinant in the coil manufacturing sector. Companies establish their reputation for dependability and exceptional quality based on a solid foundation. Experienced electric coil manufacturers, such as us, possess a substantial amount of knowledge and skill, which empowers them to effectively traverse the intricate aspects of bespoke electric coil solutions. This particular knowledge holds significant value in guaranteeing that every coil is meticulously designed to cater to the distinct requirements of its clientele, including medical equipment, aeronautical applications, and industrial gear.

The coil manufacturing sector heavily relies on innovation as a vital component. As technology progresses, the designs and materials used in coil manufacture must also evolve. The process of precision custom coil manufacturing necessitates a proactive mindset that welcomes novel concepts and technologies in order to enhance the performance and efficiency of the product. Quality Coils, Inc. is a leading company in the field of innovation, often engaging in the exploration of novel techniques and materials to improve its coil designs. The dedication to innovation shown by the company guarantees that its goods are not only at the forefront of advancements but also possess exceptional quality.

Personalization is a crucial element in coil production. Each application has distinct requirements, and commercially available solutions often fail to adequately address these demands. Custom electric coil solutions provide the necessary adaptability and accuracy to tackle these difficulties. Custom coils made to order to fulfill each customer’s exact specifications are our specialty. It stands out from competitors and maintains its position as a market leader because of its attention to detail and ability to customize solutions.

In the coil-making business, quality and dependability are very important. Customers depend on these coils to work perfectly in dangerous situations where even a small problem could have terrible results. Electric coil makers with a lot of experience know how important it is to follow strict quality control rules. Quality Coils, Inc. makes sure that every coil they make meets the strictest performance and reliability standards by putting it through a lot of tests and inspections. The fact that they are always striving for greatness is what builds customer trust and keeps them coming back.

In a rapidly developing industry, remaining on the curve is essential for progress. We accomplish this by consistently putting resources into innovative work, staying informed concerning the most recent trends and technologies, and cultivating a culture of development inside their group. Their proactive way of dealing with embracing change and pushing the limits of what’s possible in coil design keeps them at the front line of the business.

Quality Coils, Inc. stands out as a leader in creativity and quality in the fast-paced world of coil making. They continue to set the bar for precision custom coil production with their many years of experience, dedication to customizing, and unwavering drive for greatness. Nothing is certain about the future of Quality Coils, Inc. They will stay at the forefront of their field, pushing progress forward and providing unique electric coil solutions that go above and beyond what is expected. Visit their website at qualitycoils.com to find out more.

Quality Coils, Inc. has been a leader in creativity and dependability for fifty years in an industry with strict standards and fast-moving technology. From small beginnings, this global giant has set new standards for coil production. Quality Coils, Inc. has built a heritage that spans industries and countries by always striving for greatness and coming up with new ideas.

What sets Quality Coils, Inc. separated isn’t simply their life span but their capacity to adjust and fit answers to meet specific client needs. Their skill in Custom coil Manufacturing Services has permitted them to serve a different customer base, going from auto to healthcare sectors, each with its arrangement of rigid requirements.

The trip began close to the furthest limit of the 20th century, similarly as innovation was going to change the business world amazingly. Since the owners of Quality Coils, Inc. saw the commitment, they set off on a mission to fundamentally impact how coils are made. They put money into cutting-edge technology and hired the best people, which became the core of their business strategy.

The main reasons Quality Coils, Inc. is so successful are its strict quality standards and careful attention to detail. Making Precision custom coil manufacturing is more than just a service; it’s a dedication to quality that shows up in every step of the process. From the planning stage to delivery, every coil is made to go above and beyond, ensuring performance and longevity that are the best in the business.

This commitment to quality is clear in their cutting-edge factories, where new ideas are combined with careful attention to detail. Advanced automation and strict testing processes make sure that every product not only meets but often goes above and beyond the high standards that clients expect.

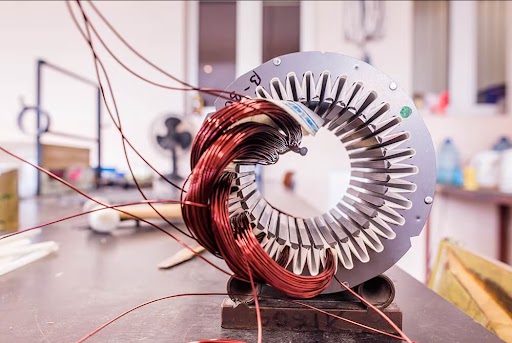

Because it only makes hydraulic coil manufacturing services, We have made a name for itself in the field. Their hydraulic coils are known for being strong and dependable, which is important in situations where failure is not a choice. These parts are needed for many industries to work in some of the toughest conditions, like building and mining.

Quality Coils, Inc.’s expert team works closely with clients to understand their practical problems and come up with solutions that are both useful and new. Their technique isn’t just about fixing issues; it’s likewise about making their clients’ organizations more important by speeding up and bringing down margin time.

We have made our production processes more environment friendly by using sustainable methods. The company wants to reduce its impact on the environment while increasing its efficiency. This pledge goes beyond the plant floor; it’s part of a larger plan that also includes reducing trash and using responsibly sourced materials.

On the occasion of their 50th anniversary of producing exceptional goods, Quality Coils, Inc. will not be taking a stroll. Part of the company’s plan for the future is to keep its promise to provide excellent customer service while investing in new technologies and entering new markets. What they want to do is not just follow the trends in their field but start them.

The way technology is changing brings both problems and chances. Quality Coils, Inc. is ready to take the lead by looking into new materials and ways of making things that could change the standards for quality and speed in coil manufacturing.

It takes a lot of work to reach the 50-year mark, especially in the fast-paced and competitive coil production business. Quality Coils, Inc. has not only lived but also grown because they are always trying to be the best and meet the wants of their customers. Visit qualitycoils.com to learn more about their custom-making options. This is a place where innovation meets skill in the search for perfection.

The history of coil production is very interesting. New ideas, hard work, and a strong loyalty to quality have marked it. You can find the story of Quality Coils, Inc. at the heart of this business. This company has been very important in shaping it. This blog looks more closely at how coil production has changed over time by using the past of this well-known business.

The narrative of coil production necessitates recognition of its humble beginnings. During the first stages, the procedure was performed manually, requiring a significant amount of time and lacking the accuracy of contemporary methods. Nevertheless, the industry’s progress was propelled by the ethos of innovation and the relentless quest for quality.

As technology got better, more people started to want unique coil options. This change was a big turning point in the business world. When custom coil manufacturers came on the scene, they brought a new level of accuracy and flexibility. They were designed to meet the unique needs of many fields, from technology to cars, and were very important in the creation of specialized goods.

The progress made in making coils hit a new level when high-quality custom coil manufacturers came along. These companies raised the bar for quality and efficiency, making sure that every coil met the exact needs of its purpose. They used cutting-edge technology and strict quality control to make coils that were not only dependable but also worked better than others.

Magnetic coil manufacturers were also very important to the growth of the business. Their main business was making coils that were used in magnetic devices like transformers and inductors. Their knowledge of how to work with magnetic materials and how complex magnetic fields work made a big difference in the progress of coil technology.

Quality Coils, Inc. stood out in the middle of all the change. After being built on the ideas of innovation, quality, and customer happiness, the company rose to the top of the coil production industry. We have set the bar for success by focusing on unique solutions and high-quality goods. It was one of the first companies in its field to do this.

As we contemplate the next period, the coil manufacturing sector is propelled by the forces of innovation and technical progress. Manufacturers are increasingly exploring novel materials, processes, and designs because of the growing need for coils that are more efficient, dependable, and customized. The next period has great potential for the coil manufacturing industry, with a multitude of prospects and avenues for expansion.

The progression of coil production serves as evidence of the industry’s ability to adapt, introduce new ideas, and maintain high standards of quality. From its modest origins to the intricate procedures of the present day, the trajectory has been extraordinary. Quality Coils, Inc. has played a substantial role in the historical development of the industry, making notable contributions to its expansion and establishing benchmarks for exceptional performance. As we progress, the enduring impact of qualitycoils.com and the broader industry serves as a source of inspiration and influence in shaping the trajectory of coil production in the future.